Production & Logistics ❤

Resilient, coordinated end-to-end production & logistics processes lead to greater efficiency and fewer interface problems.

Resilient, coordinated end-to-end production & logistics processes lead to greater efficiency and fewer interface problems.

Matthias Hilpold, Head of Business Application Services, Information Technology

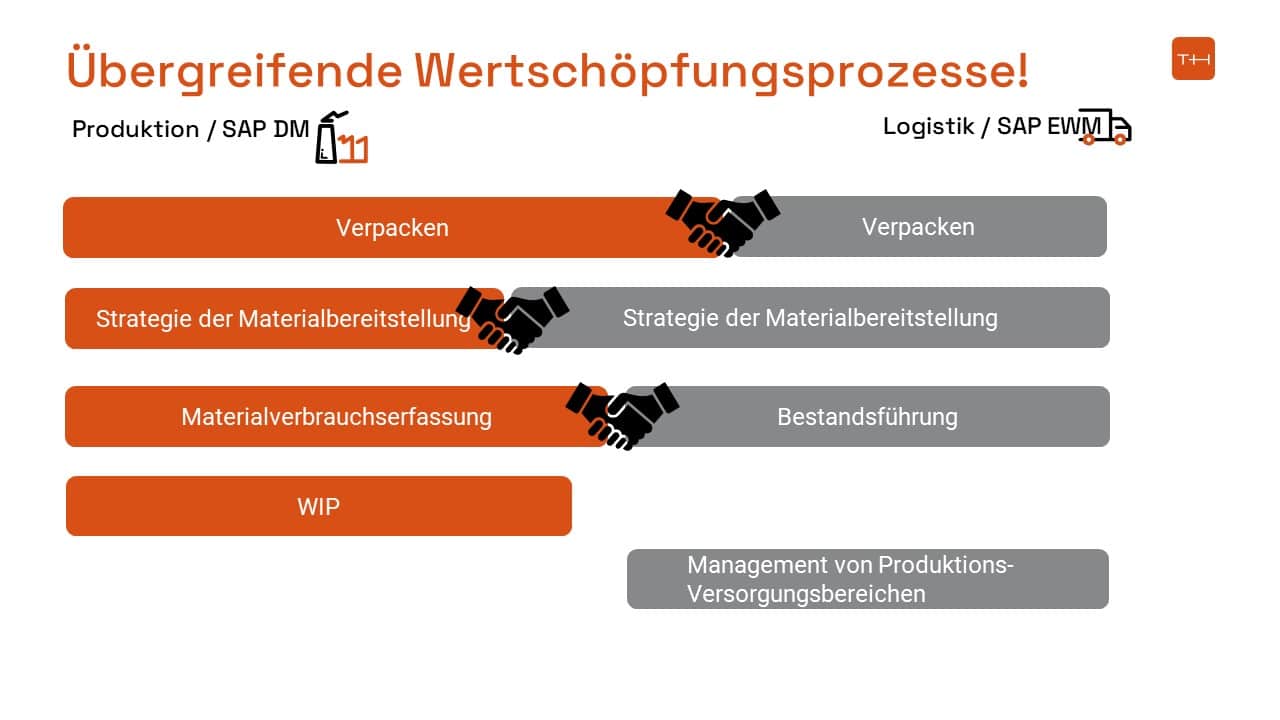

In order to avoid process breaks or even silos at departmental boundaries, it is necessary to place the value creation process as a guiding principle at the center of the optimal process design.

In practice, functions are often provided and maintained twice in production and logistics. In extreme cases, this leads to logistics functions being individually replicated in the MES and/or, conversely, typical MES functions being integrated into the logistics software. The goal is a continuous, standardized process across integrated systems and that functions are mapped where they are ideally implemented in the standard system. This does not necessarily go hand in hand with organizational departmental boundaries.

We at Trebing + Himstedt have been developing and implementing digitization in discrete manufacturing from A to Z since 1992. From brainstorming in workshops to implementation, provision of the system landscape, and training, we accompany our customers in their sustainable digital transformation.

Event-based, on-demand supply of materials in production.

Goods movements of material on the store floor.

Order-related / -independent (scrap) consumption based on actual data.

Goods receipt at packing or yield reports at the last operation.

For example, work with us in a joint workshop to identify the duplicates and duplicate tasks in your processes and determine in which system the functions are to be implemented in the standard in the future.

We help production and logistics managers build flexible and efficient production by providing information on demand through digitization, standardization and linking of integrated end-to-end processes, assets and people.

Talk to us about how we can make your production logistics more efficient.

Chris Leinemann

Customer Solution Advisor