Celonis Process Mining in Production

The Celonis EMS (Execution Management System) is a cloud-based system for process analysis and provides optimization recommendations. Based on process mining technology, end-to-end processes in the company are continuously analyzed and checked for weaknesses using artificial intelligence (AI). In addition, automation solutions support the process or perform steps automatically.

Process Mining provides a real-time X-ray 4.0 of production processes – a living, breathing, moving picture that reveals where inefficiencies are hidden. The actual as-is process is compared with the planned to-be process models to identify deviations that cause inefficiencies.

At the heart of process mining are event logs, or event logs. Event Logs structure the digital footprints in your processes and prepare them for the “X-ray” that Celonis provides.

Along this process twin created on event logs, various key figures can be collected and in-depth analyses can be performed. A new level of transparency is created. This enables a living system of key performance indicators along the entire value chain (end-to-end processes) and the systematic identification of optimization potential.

Furthermore, target and actual processes can be compared with each other (conformance checking). Deviations are automatically detected, quantified and highlighted.

Whitepaper: Celonis Process Mining in Production

Basics of Process Mining and Celonis

Use case: Digital lean management with process mining

Use case: Successful system transformation with process mining

Current trends, recommendations best practices

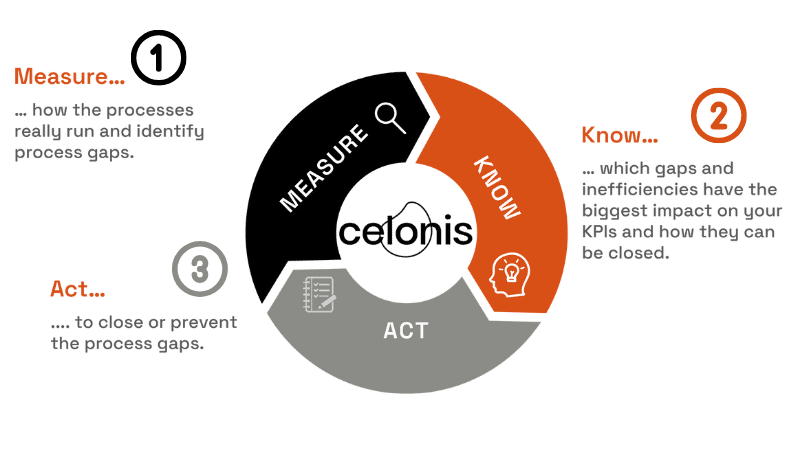

In 3 steps to the optimal production process

From measurement to knowledge to action

Current status: Process capacities are measured and execution gaps are identified by analyzing and visualizing the log file data. This initial step creates transparency in your processes and shows how they really work.

Target state: Based on machine learning, Celonis automatically recommends measures to improve process behavior. For this purpose, it is shown which inefficiencies have the greatest influence on the defined KPIs (root cause analysis).

Celonis supports the daily process execution. On the one hand, process steps can be automated (action flows). On the other hand, Celonis can send employees a recommendation about necessary activities (action engine).

Advantages of using Celonis EMS:

High level of transparency along the end-to-end processes

Simple data connection of complex, heterogeneous process landscapes

Potential for process optimization is tracked down to a very granular level

Provides data basis for other optimization activities (CIP, idea management, projects)

Volatile key figures become explainable through deep transparency

Process execution closer to the target process, supported by automation

Ready for the next step?

Learn more about transparent production with process mining and the agile approach for the digital transformation to the smart factory.

Chris Leinemann

Customer Solution Advisor